The Project Manufacturing features integrate Costpoint with Costpoint Manufacturing Execution and Costpoint Shop Floor Time, which allow you to plan and cost jobs based on project requirements and track details while maintaining the integrity on the manufacturing floor. Also, the integrated accounting, project management, and materials functionalities allow you to resolve day-to-day capacity and resource planning, procurement, inventory, and production issues.

Costpoint Manufacturing Execution and Costpoint Shop Floor Time provide you with the ability to maximize efficiencies on the manufacturing floor. This includes the following:

Accurately collecting labor against manufacturing orders and routings steps

Recording shop floor activity

Planning and dispatching

Improving production quality

Providing real time visibility into the production process

Accurately and efficiently transacting material movements to provide the overall lean manufacturing approach

Deltek Costpoint Manufacturing Execution is an operation process management system that manages work and quality processes for manufacturing, repair, maintenance, and overhaul of highly engineered complex products. Costpoint Manufacturing Execution streamlines processes for all planning and production personnel and provides complete quality management and device history, starting with component inspection and continuing through manufacturing, inspection, and aftermarket service of the product.

Deltek Costpoint Shop Floor Time is a time and attendance system that collects, evaluates, and manages data from your workforce. It allows you to record and control time and attendance activities, absence events, and labor transactions. It also handles work handles, pay policies, and accruals calculations.

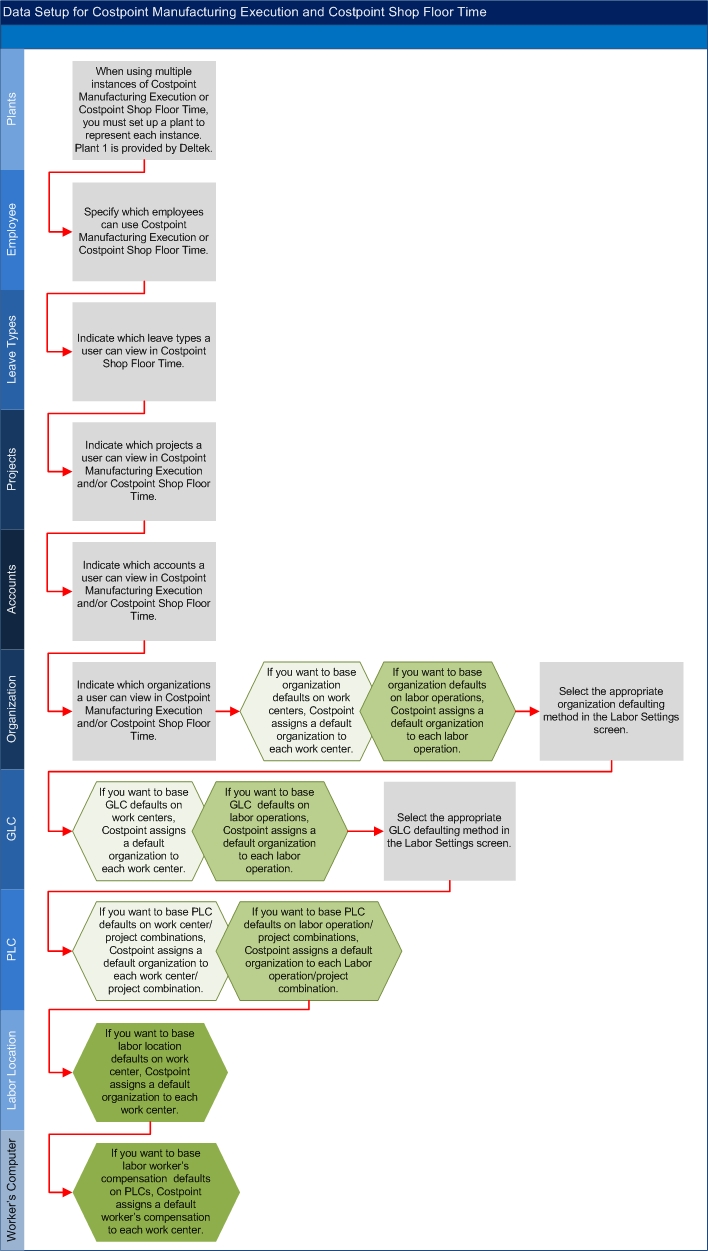

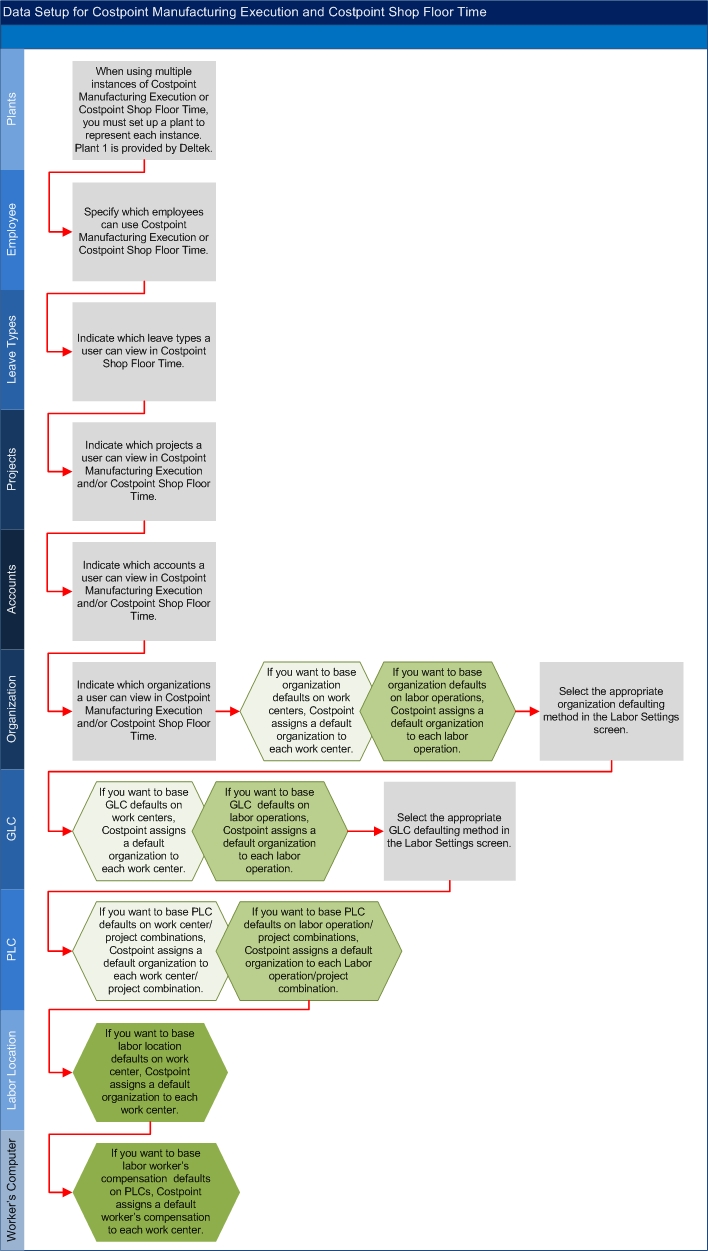

The following table describes how Costpoint integrates data with Costpoint Manufacturing Execution and Costpoint Shop Floor Time.